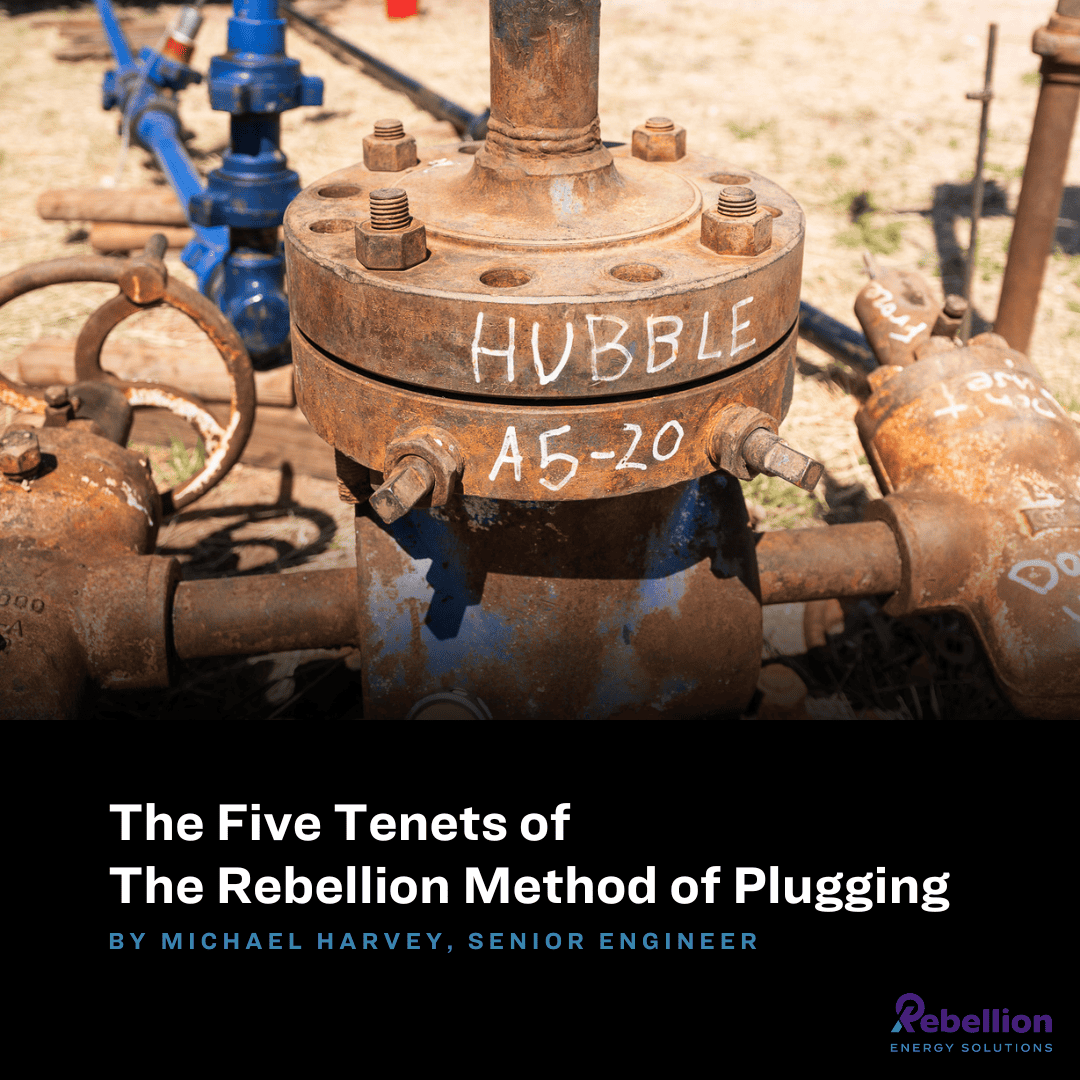

The Five Tenents of The Rebellion Method of Plugging

By Michael Harvey, Senior Engineer

High-quality Plug & Abandonment (P&A) work begins prior to cement placement and is driven by disciplined engineering and operational judgment under uncertainty. This is particularly critical when addressing orphan wells that may have been idle for extended periods of time with unknown pressures, corrosive fluids, and surface equipment integrity.

Many orphan wells have incomplete historical records and aging wellheads, valves, and production trees that have degraded over time and have begun the release of thousands of cubic feet of gas. Rebellion Energy Solutions has the expertise to recognize these issues and mitigate them through operational planning and exceeding industry best practices in Plug and Abandonment.

5 Tenets of Plugging:

- Complete Barriers: Formation to formation barriers are beyond industry standard but critical to a permanent seal.

- Precise placement of Cement plugs: Cement plugs are placed at key depths using verified blending and placement methods to ensure long-term isolation and prevent methane migration.

- Engineered Plugs: A certified Professional Engineer considers well conditions and designs for superior bond and seal.

- Oversight & Validation: Onsite adherence to procedures as closely as possible and post job validation of work is required. Safety on location is priority.

- Reporting: Records are strictly kept in-line with company policy for review and verification at any point in time as well as clear post issuance monitoring procedures.

High-quality Plug & Abandonment is never achieved using perfect information or having ideal well conditions. It is expected to have challenges, but by using the Rebellion Methods, these challenges are mitigated by using strong operational planning, experienced execution, and sound operational judgment under aspects of uncertainty to reduce risk, control costs, and abandon wells safely.